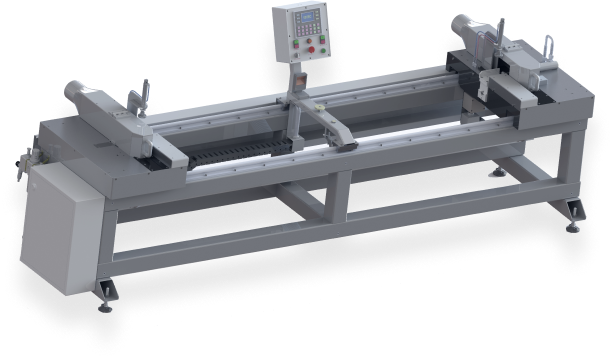

- Максимальная производительность оборудования и высокая точность изготовления готовых конструкций

- Минимальные затраты на изготовление конструкций и максимальная доходность предприятия

- Максимально эффективное использование производственных площадей

По производительности и точности изготовления превосходит оборудование лучших мировых производителей.

Работает у самых крупных производителей Российской Федерации и Республики Беларусь